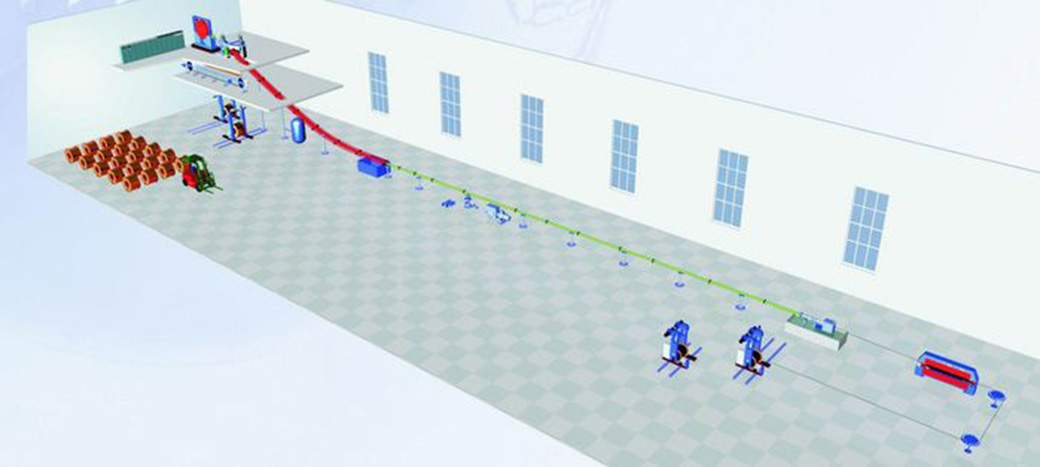

MV CCV Line for Medium Voltage Cable

35kV Cable Extrusion Line, Triple Extrusion

This MV CCV line is typically designed for triple extrusion of XLPE insulated medium voltage cables for use at voltages ranging from 6kV to 35kV. By absorbing world's advanced catenary continuous vulcanization (CCV) technology, Baicheng Miracle has developed and manufactured this three-layer extrusion dry cure cross-linking line in-house, which was the first in the domestic market.

Our independently developed three-layer crosshead has obtained national patent, due to its great convenience and ease of alignment. Furthermore, the patented control technology in catenary line is characterized by high resistance against interference, ensuring an exceptional stability.

Medium voltage cables manufactured by this extrusion line are supplied in diverse sizes, diameters, lengths, layer thickness and other technical specifications. Depending on applications, the produced XLPE insulated power cables can be laid directly in the ground or buried in underground ducts, also suitable for submerged under water and working on overhead transmission systems.

- Triple extrusion process for XLPE insulated cables of voltages up to 35kV;

- Capable of manufacturing power cables used for a variety of applications;

- Computer control, touch screen operation, Siemens TIA Portal software, and high-resolution HMI interface;

- Triple crosshead provides great convenience and ease of alignment;

- Customer-specific modified versions are available, which deviate from the standard version in speed adjustment by control of CV tube temperature;

MV Cable Triple Extrusion Line (6 Sections)

| Voltage class | XLPE: 6-35kV | ||

| Conductor size | Cu: 25-630mm2 Al: 35-800mm2 | ||

| Max. cable weight | 10kg/m | ||

| Max. cable diameter | 70mm | ||

| Cable construction | Conductor screen (inner semiconductor layer) 0.5-2mm |

Insulation 3.4-12mm | Insulation screen (outer semiconductor layer) 0.5-2mm |

| Line speed | 0-30m/min | ||

| Line execution | Half catenary | ||

| Length of cross-linking section | Approx. 41m/6 sections (6 tubes) |

||

| Length of pre-cooling section | 12m/2 sections (2 tubes) | ||

| Length of cooling section | 54m/9 sections (9 tubes) | ||

| Arrangement of extruders | Φ65 extruder for conductor screen Φ150 extruder for cross-linked polyethylene (XIPE) Φ90 extruder for insulation screen |

||

| Electricity | Installation capacity 750kVA | 380V ±10% 50Hz±1% | 3 phase 4 wire |

| Water | Water pressure 0.2-0.6MPa | Water consumption 15m3/h (circulating water from reservoir) |

|

| Compressed air | 0.6-0.8MPa | Air consumption 0.8m3/min | |

| Nitrogen | Pressure 2.0-2.5MPa | Purity 99.5% | Consumption 1-2m3/h |

| Nitrogen storage tank | ≥6m3 (1 pc) | ||

MV Cable Triple Extrusion Line (9 Sections)

| Voltage class | XLPE: 6-35kV | ||

| Conductor size | Cu: 25-630mm2 Al: 35-800mm2 | ||

| Max. cable weight | 10kg/m | ||

| Max. cable diameter | 70mm | ||

| Cable construction | Conductor screen (inner semiconductor layer) 0.5-2mm |

Insulation 3.4-12mm | Insulation screen (outer semiconductor layer) 0.5-2mm |

| Line speed | 0-30m/min | ||

| Line execution | Half catenary | ||

| Length of cross-linking section | Approx. 54m/9 sections (9 tubes) |

||

| Length of pre-cooling section | 12m/2 sections (2 tubes) |

||

| Length of cooling section | 90m/15 sections (15 tubes) | ||

| Arrangement of extruders | Φ80 extruder for conductor screen Φ175 extruder for cross-linked polyethylene (XIPE) Φ100 extruder for insulation screen |

||

| Electricity | Installation capacity 1050kVA | 380V ±10% 50Hz±1% | 3 phase 4 wire |

| Water | Water pressure 0.2-0.6MPa | Water consumption 15m3/h (circulating water from reservoir) |

|

| Compressed air | 0.6-0.8MPa | Air consumption 0.8m3/min | |

| Nitrogen | Pressure 2.0-2.5MPa | Purity 99.5% | Consumption 1-2m3/h |

| Nitrogen storage tank | ≥6m3 (1 pc)×2 | ||

Extruder & Crosshead

Extruder

Extruder

Three-layer Crosshead

Three-layer Crosshead

-

65/20D Extruder

- Max. screw speed: 46.5rpm

- Gear reduction ratio: 32:1

- Extrusion output: 35kg/h

- Used for extruding conductor screen layer (inner semiconductor layer)

-

90/20D Extruder

- Max. screw speed: 41.5rpm

- Gear reduction ratio: 36:1

- Extrusion output: 60kg/h

- Used for extruding insulation screen layer (outer semiconductor layer)

-

150/25D Extruder

- Max. screw speed: 40rpm

- Gear reduction ratio: 37.5:1

- Extrusion output: 250kg/h

- Used for extruding insulation layer

-

Technical Parameters

- Conductor diameter: 6-34mm

- Max. cable diameter: 70mm

- Extrusion thickness:

First layer: 0.5-2.0mm

Second layer: 2.0-12mm

Third layer: 0.5-2.0mm - Heating method: oil or water heating

-

Features

- Designed with circulating distribution flow channel and restrictor ring, the length of flow distributors and crosshead is greatly shortened in contrast to other three-layer crosshead, thus reducing its weight;

- Easy to disassemble for convenient cleaning;

- Providing great convenience and ease of alignment during extrusion process;

Control System

- Highly resistant to interference, minimum fluctuation of cables in tube, ensuring stable running and easy to maintain;

- Control system is placed at the middle part of heating zone, it can protect cables from contacting the tube wall during heating process;

- When the control receives the signal of cable position, the rotation speed of lower capstan (pulling) will be adjusted accordantly;

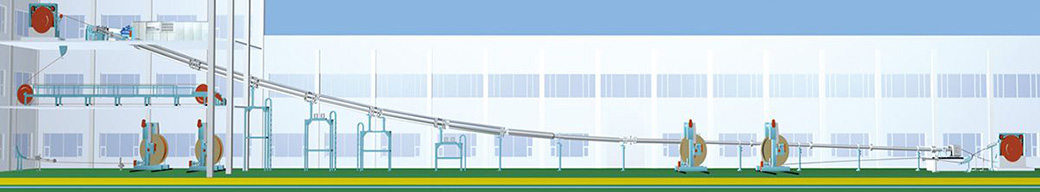

Portal Upper Beam Travelling Pay-Off Stand

- Gantry structure with mechatronic design, achieving reciprocating motion while keeping the alignment of center line when paying off;

- Shaftless pay-off reel moves up and down between two posts, driven by AC motor;

- Dancer is adopted for speed control;

- Pay-off stand can achieve rotation in both positive and negative directions;

- Touch screen allows operator to input technical parameters easily and conveniently;

- The pay-off stand is independently controlled;

- Drum diameter: 1600-2500mm (GB4004-84, PN Type)

- Drum width: 1180-1900mm

- Drum weight: Max.16t

- Pay off tension: 5000N

- Main drive: 5.5kW DC motor, 4 quadrant, Parker 590P (original Eurotherm)

- Dancer: used for speed control, keeping the cable aligned with center line when paying off

Capstan

- Used for pulling cable conductors from lower level to desired height;

- Belt wrap capstan (or caterpillar capstan) operates synchronously in CCV line;

- Conductor positioning unit ensures the cable conductors of different sizes placed in alignment with the center of the crosshead;

- Transmission unit adopts fixed base, spiral bevel gear reducer and DC motor;

- Pulling method: belt wrap capstan

- Capstan wheel diameter: 2000mm

- Adjusting range: 0-30m/min (four gear shifts)

- Pulling force: max. 30kN

- Belt contact length: 3m or above

- Cable diameter: up to 100mm

- Speed sensor equipped with line speed meter

- Main drive: 11kW DC motor, Parker 590P drive

Belt-type Twister with Angle Adjustment

- Twister weight: 650kg

- Overall dimensions: 1525mm×975mm×1243mm

- 26 grooved passive wheels are mounted on both sides. The distance between wheel sets on both sides is adjustable ranging from 2 to 200mm. The wheel sets move on both sides.

- The rollers on both sides can be adjusted by ±50mm, which is calibrated by the caliper. Max. wire diameter passing through is 70mm.

- The center height is 1m. (If the height is not consistent with the outlet of end seal, cut off the footing to change the center height.)

- The twister comes with a welded machine body, a passive transmission mechanism, and a semi-enclosed stainless steel cover.

- It’s installed between the end seal and pull-out capstan.

- Belt width: 150mm, thickness: 20mm

Accumulator & Upper Auxiliary Caterpillar

-

Accumulator

-

End Seal

-

Extruder

-

Lower Capstan

-

Pay off Stand

-

Upper Capstan

-

35kV Cable Extrusion Line