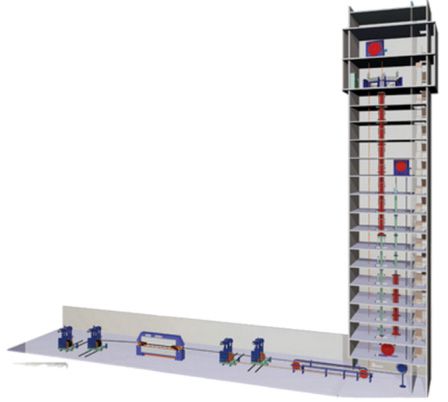

Vertical Continuous Vulcanization (VCV) Line for MV, HV and EHV Cables

35-220kV Cable Extrusion Line, Triple Extrusion

Baicheng's vertical continuous vulcanization line (VCV line) is designed in response to the popularity of XLPE cables in high voltage application. In particular, the quality of high voltage and extra high voltage power cables plays an essential role in the safety of electric system.

This vertical cable extrusion line is particularly used for manufacturing high quality XLPE insulated power cables of voltages ranging between 35kV and 220k. It mainly comprises pay-off stand, accumulator, capstan, extruder, three-layer crosshead, take-up stand, etc.

- Manufacturing the full range of medium voltage (MV) to extra high voltage (EHV) cables;

- Triple extrusion process for XLPE insulation;

- Capable of manufacturing power cables used for a variety of applications;

- Long and stable production runs;

- L-type and U-type are available;

- Triple crosshead provides great convenience and ease of alignment;

- Customer-specific modified versions are available to suit individual requirements;

| Voltage class | XLPE: 35-220kV | ||

| Conductor size | Cu: 150-2000mm2 Al: 150-2000mm2 | ||

| Max. cable weight | 34kg/m | ||

| Max. cable diameter | 140mm | ||

| Cable construction | Conductor screen (inner semiconductor layer) 0.6-2mm |

Insulation 4.5-40mm | Insulation screen (outer semiconductor layer) 0.6-3mm |

| Wire core diameter | 14.6-56.1mm | ||

| Line speed | 0.2-8m/min | ||

| Line execution | VCV tower (U type/L type available) | ||

| Arrangement of extruders |

Φ80-Φ175-Φ90 three-layer extrusion Φ80 extruder for conductor screen Φ175 extruder for cross-linked polyethylene (XIPE) Φ90 extruder for insulation screen |

||

| Electricity | Installation capacity 1000kVA | 380 V ±10% 50Hz±1% | 3 phase 4 wire |

| Compressed air | 0.6-0.8MPa | Air consumption 0.5m3/min | |

| Nitrogen | Pressure 2.0-2.5MPa | Purity 99.5% | Consumption 1-2m3/h |

Extruder & Crosshead

Triple extrusion lines have three extruders connected to one common three-layer crosshead for the simultaneous extrusion of conductor screen layer (inner semiconductor layer), insulation layer and insulation screen layer (outer semiconductor layer).Control System

The control system makes sure the entire VCV line run synchronously. All the electrical drive systems can work simultaneously, or to be controlled independently by single machine. Emergency stop is possible for individual units such as pay-offs, accumulators, extruders and take-ups respectively.

Capstan

Accumulator & Upper Auxiliary Caterpillar

-

Accumulator

-

End Seal

-

Extruder

-

Lower Capstan

-

Pay off Stand

-

Upper Capstan